In the world of modern technologies, where precision and reliability determine the market success of a finished product, the choice of a casting component supplier is crucial. A cast iron foundry is not just a production plant; it is a strategic partner in the creation of machines, hubs, turbine housings, generator frames, or drive elements. For many industrial sectors, iron castings are the foundation of installations and specific components.

Contemporary foundry technology is a combination of hard physical work and advanced engineering; therefore, a modern cast iron foundry must merge craftsmanship with digitalization. The use of simulation software allows for predicting potential casting defects, such as shrinkage or gas porosity, even before the first mold is poured, which significantly reduces costs and shortens the component creation time.

Wide range of materials

A modern cast iron foundry must offer flexibility in material selection, tailored to the specific operating conditions of individual elements. At ELZAMECH, we have been dealing with castings for over 30 years, so we perfectly understand the properties required for a given hoisting, machine, or wind turbine component. We supply two key grades, according to their structural requirements.

Grey cast iron up to 30 tons, according to the standard PN-EN 1561:

- EN-GJL-100

- EN-GJL-150

- EN-GJL-200

- EN-GJL-250

- EN-GJL-300

Ductile iron up to 22 tons, according to the standard PN-EN 1563:

- EN-GJS-350-22 (room temperature impact strength)

- EN-GJS-350-22-LT (low temperature impact strength)

- EN-GJS-350-22-RT (room temperature impact strength)

- EN-GJS-400-18-LT (impact strength at -20˚C and -40˚C)

- EN-GJS-400-18-RT (room temperature impact strength)

- EN-GJS-400-18

- EN-GJS-400-15

- EN-GJS-500-7

- EN-GJS-600-3

- EN-GJS-700-2

Curiosity: thanks to its spherical graphite structure, ductile iron can match the strength of some steel grades while retaining significantly better castability and ease of machining. This material fundamentally revolutionized heavy machinery construction in the 20th century.

Modern laboratory facilities

A contemporary cast iron foundry should possess its own laboratory. The client must receive assurance that every casting meets rigorous standards, is safe, and ready for use. Production at the ELZAMECH plant is carried out in accordance with the Integrated Management System meeting the requirements of standards: ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018. Additionally, the authorizations of the Transport Technical Supervision allow for the production of specialized iron castings for:

- railcar tipplers,

- ship lifts,

- rail vehicle hauling winches,

- hauling winches for railcar shunting.

Our experience in the foundry industry ensures we provide extensive testing of iron castings:

- chemical composition,

- metallographic,

- mechanical strength,

- defectoscopic (NDT),

- 3D measurement,

- consulting and technical advice in the field of foundry technology.

Furthermore, we utilize only modern equipment for controlling the chemical composition of liquid metal, non-destructive, metallographic, mechanical strength testing, and dimensional control, which guarantees the reliability of our products.

We also apply CAD support systems (Solid Edge) at every stage of design and production preparation. When implementing prototypes, we conduct detailed simulations of the pouring and solidification process. This enables us to design the product faster, optimize the production process, and minimize risks. Our Technology Department offers comprehensive services, ensuring the highest quality and efficiency in executing even the most demanding orders.

Comprehensive services: from design to finished product

Modern contractors increasingly seek the "one-stop-shop" model. A cast iron foundry that offers not only the raw casting but also its machining, painting, or assembly allows for savings on logistics and reduces the risk of quality disputes between the casting supplier and the machining shop. We perfectly understand this approach, which is why we approach every project comprehensively, delivering products ready for immediate use.

The modern paint shop at the ELZAMECH plant enables shot blasting, metallization, and painting of castings in accordance with individual customer requirements. Innovative technological solutions guarantee high quality and adaptation to specific project needs. Additionally, an advanced ventilation system ensures work safety and environmental protection.

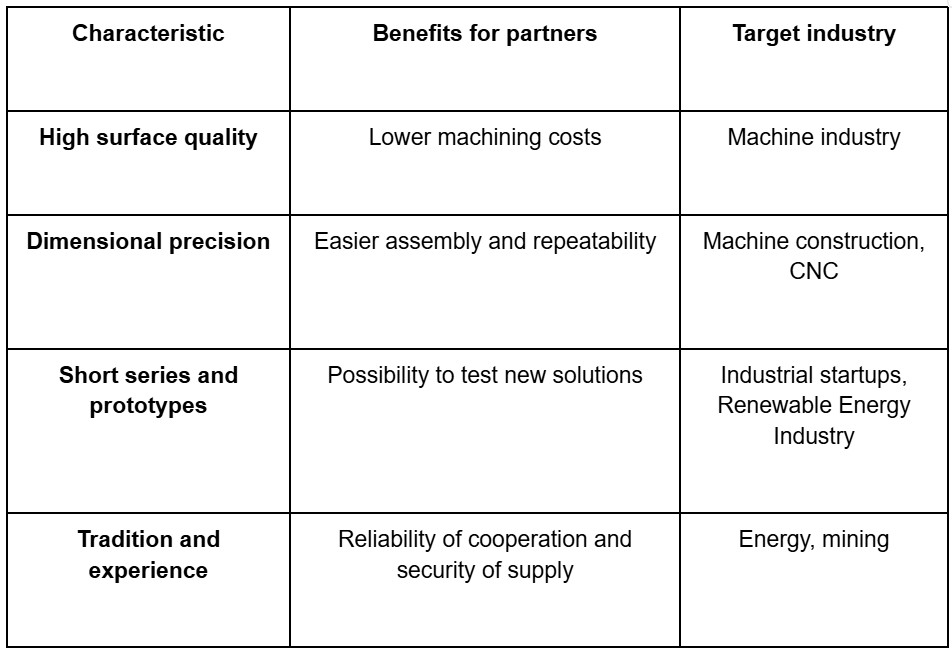

Why choose the ELZAMECH cast iron foundry as your partner?